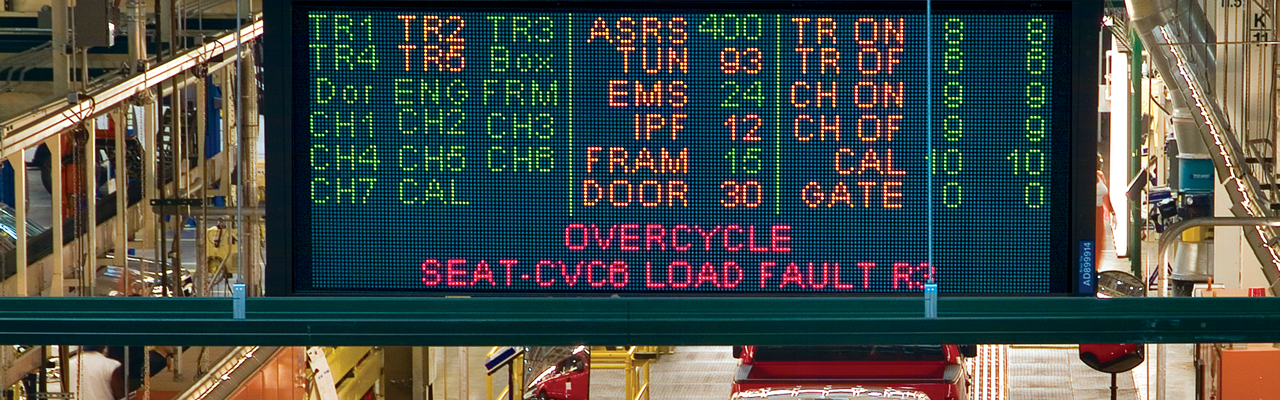

There is confusion in the marketplace when considering which technology to deploy for your Visual Andon System. There are two prominent technologies that are widely in use in the Manufacturing Environment, namely, Industrial LED Backlit LCD Displays and Industrial Full Matrix LED Displays. Recent advances in the consumer market are driving a trend towards LCD displays, but before making this capital investment, let’s explore the benefits of both technologies.

Note: Moving forward when I say LCD Displays, I am referring to Industrial LED Backlit LCD Displays. Also, when referring to LED Displays, I mean Industrial Full Matrix LED Displays.

Display Manufacturing Environment is Key

Your manufacturing environment is a key factor in determining which technology to choose. The following list describes a few areas to pay attention to when considering which technology to go with.

-

Display Temperature: LED Displays often have a wider operating temperature range compared to traditional LCD Displays. Some LED displays are designed to operate in a range of -20°C to 65°C, while LCD displays may have a more limited range, such as 0°C to 40°C. However, these values can vary, and it's crucial to check the specifications of the specific models you are considering.

-

Cleanliness of Display: Both LED and LCD displays can benefit from proper enclosures to protect them from harsh environments. However, enclosing displays may affect internal operating temperatures, and it's essential to consider the design and ventilation of enclosures to prevent overheating.

-

Ambient Lighting: LED Displays generally have better contrast and brightness compared to traditional LCD Displays. This can make LED displays more visible in brighter conditions, such as outdoor environments with direct sunlight. The improved visibility is often attributed to the backlighting technology used in LED displays. However, specific performance can vary among different models and technologies.

Pay Attention to Durability and Life Expectancy

The two big indicators of this are mean time between failures and warranty.

- Mean Time Between Failures (MTBF): LED Displays are often rated for 100K hours whereas LCD Displays are rated for 60K hours.

- Display Warranty: Typically the warranty for LED Displays is 5 years comparatively a LCD Display warranty is 3 years

Note the Content Display Abilities

- Color Display Options: Both technologies support a full range of color options

- Alphanumeric vs Pictures & Graphs: LCD Displays support all images due to their high-resolution nature i.e. 1080p, whereas LED Displays are ideal for alphanumeric data.

- Display Viewing Distance: The viewing distance for both LCD and LED displays can depend on factors such as display size, resolution, and the content being shown. While it's stated that LCD displays may be viewed better within 100 feet, and LED displays are commonly used for greater distances, specific factors like pixel pitch and resolution can also influence viewing distances.

- Modularity/Scalability of Display: LED displays are often more customizable and modular, allowing for specific configurations based on the overall matrix of pixels. LCD displays, especially in consumer markets, may follow standard sizes like 55 inches. The level of customization and scalability can vary among different models and product lines.

Determine the Cost of Ownership

- Display Purchase Price: Capital expense per LCD Display is cheaper compared to an LED Display until you exceed the consumer LCD/TV market size.

- Installation/Networking Cost of Display: The cost of installation is similar per unit regardless of a LCD or LED Display.

- Maintenance Cost/Mean Time To Repair: An LCD Display is one module and will have to be replaced completely if a failure occurs. This may require shipping it back to the factory for replacement. LED Displays are more modular and individual components can be replaced in the field without much downtime.

Hopefully the information provided regarding Visual Andon Technology has helped answer some of your questions regarding Visual Andon Displays and the systems they support. Information shown on Andon Displays is vital to overall efficiency, lean processes, and flow of materials in factories around the globe.

Electro-Matic Visual, Inc specializes in helping customers choose the right technology for their individual applications. If you would like to learn more, feel free to visit us online or give us a call at 866-998-0990.