Downtime is a serious threat to any manufacturing business. One of the most dreaded scenarios within a manufacturing plant is that if one area backs up, it can have a snowball effect on other areas waiting for the completion of prior processes to deliver parts to them. The old saying “time is money” is very true in these manufacturing plant situations. The longer amount of time it takes to complete processes and finish products, the more money it costs to get those products out the door. When you reduce downtime in manufacturing and the amount of time that people or machines are idle, it will be more efficient for the business’s bottom line. Learn how to improve manufacturing efficiency and downtime with the nine tips below:

Reducing Downtime in your Facility

Motivating and inspiring your employees is a big first step to reducing downtime in your manufacturing plant. It is important to inspect and repair all machinery, and make upgrades so that your employees have the optimal environment to achieve production goals. With a combined effort, correct equipment, and good atmosphere, you can significantly reduce downtime in your manufacturing plants.

Increase and Improve Staff Communication

Staff communications between managers and employees is proven to be essential to improve manufacturing efficiency between departments. For an employee to feel a part of the team, the supervisor should explain the relationship between downtime and business profits to help employees feel like a part of the team and that their opinions are heard when making important decisions and operation strategies. Keeping your employees involved is key to increasing productivity. Happy and motivated staff members do a better job of contributing to the ultimate goal to reduce downtime in manufacturing settings.

Hold Regular Staff Evaluations

The majority of companies conduct regular performance reviews, but you can make yours more powerful by including a discussion of manufacturing downtime. Regular employee evaluations are standard, but the key is how they are administered. Evaluations need to be honest and straightforward. Evaluations should focus on what management views as areas of excellence and areas needing improvement. Armed with the proper feedback, employees stay motivated to increase their areas of strength, but also fight to reduce manufacturing downtime.

Set Specific Goals to Improve Manufacturing Efficiency

Set both daily and quarterly incentive goals to reduce errors and improve productivity—both of these can help reduce downtime in manufacturing dramatically.

With motivated and inspired staff, downtime is minimized. Employees who understand the role they play in the manufacturing process provide more valuable feedback and work at more efficient levels. Using employee suggestions on how to decrease downtime, increase morale, and produce more goods is also important. Listen to your employees on the production line—because they’re the ones involved hands-on with production, they can offer valid ideas on how to decrease downtime.

Listening to your production line employees’ suggestions also makes them feel part of the decision-making process. Educating employees about each part of the manufacturing process may help them better understand their specific role and job. Managers who make sure that all employees have incentives to excel and consider their suggestions are also rewarded with higher productivity. This is true across any industry.

Conduct Regular Manufacturing Equipment Maintenance

Machinery malfunctions need to be prevented to minimize manufacturing downtime. Businesses that monitor, inspect, update, and repair their machinery create the right atmosphere for meeting goals to help eliminate downtime. Machines that continuously jam or break down have a huge negative impact on downtime outcomes. Regular maintenance is critical to keeping machines operating at their best for the longest stretches of time possible.

Upgrade Manufacturing Equipment

Replacing obsolete equipment to improve manufacturing efficiency is an essential piece to reducing manufacturing downtime. Outdated machines slow down the manufacturing process. Installing new equipment should allow your plant floor to stay up-to-date on the latest products and technologies. Upgrading to LED lighting in your facility and industrial LED displays are a great place to start.

The Overall Equipment and Effectiveness (OEE) measurement is frequently used to gauge a plant’s effectiveness. There are several common causes of efficiency loss:

- Breakdowns

- Set up Losses

- Minor Stoppages

- Reduced Speed

- Start-up Issues

- Rework to Resolve Quality Issues

Ethernet communications network in your plant will also allow you to harvest actionable energy management data from connected drives, energy meters and process controllers. This will all help eliminate energy waste.

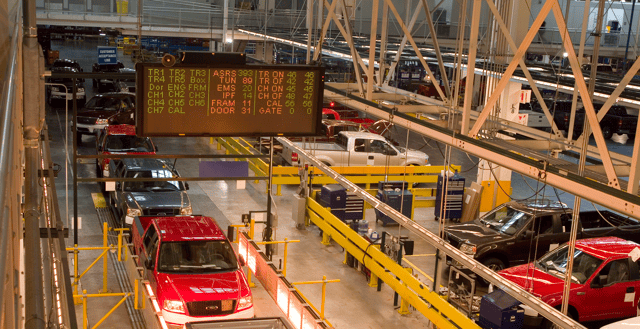

Track Manufacturing Downtime Carefully

Knowing when, where, and how downtime occurs is essential to knowing how to prevent it. An early step toward reducing unexpected production backups or outright downtime can be achieved by carefully and accurately tracking when and where downtime occurs. Automatic trackers detect downtime immediately and feed this information out to the factory floor for real-time viewing. Alerts are visible and show the exact location issues have occurred. This allows you to figure out why each instance happened. When you know that user errors are causing the majority of your noted stalls, you know what changes to make and what to prioritize in your efforts.

Properly Train Production Line Employees

User error is one of the top causes of downtime on a production line. Some reports say as much as 70% of downtime can be attributed to user error. There are numerous ways that operators can cause a machine break down, so proper training shouldn’t be taken lightly. Proper education is imperative for machine operators to improve manufacturing efficiency and optimal production results. They need to know how to use tools effectively. Teaching your team members so they're capable of operating machines correctly will result in less operator errors that ultimately cause slowdowns and downtime.

Replace the CPU and Software

Instantly gain benefits of a new platform without changing your hardware. This enables you to preserve your investment in application design and embedded process knowledge all while extending the life of your existing control system incrementally. The new operational capability you provide helps eliminate previous downtime areas that were out of reach of the old CPU. New software provides the basis for any technology upgrades you will want to do in the future. New software will improve manufacturing efficiency and provide a smooth transition for operating personnel to the new technology.

Create a New Technology Plan for Your Manufacturing Plant

Develop a strategic enrollment plan that allows you to integrate new technologies into your plant with a modernization program. Implementing a modernization program is a good way to reduce the amount of unplanned downtime. A step-by-step plan is a good approach that will not only increase uptime, but also provide a range of benefits for your processing facility. In modernizing the technology in your plant you may choose to install an industrial Ethernet plant network, standardize on single PLC software, introduce networked HMI’s. Budgets can be more easily maintained with smaller upgrades that are planned over time. They can possibly be financed by a multiple departmental budgets, which can ease the upgrade processes.

Taking the steps to reduce downtime in manufacturing settings can seem overwhelming, but the money saved, and additional profits earned from making adjustments to reduce downtime are worthwhile. Download the guide below to learn more about how you can improve efficiency in your manufacturing plant.